Agricultural Economy

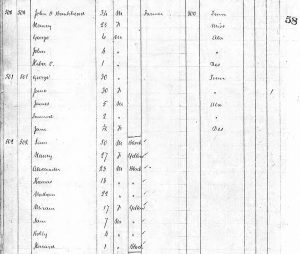

Agriculture, including raising livestock, was the major force in the local economy, with Box Elder residents branching out into the nearby countryside. In the 1850s most planting and harvesting was done by hand or by horse or oxen-drawn wooden implements. Agriculture bought the first (and only documented) slave labor to Box Elder in about 1856 when John Bankhead, a former southern slaveholder and resident of North Willow Creek (Willard) brought in a cylinder threshing machine and contracted out its services. Two of his (legally former) slaves, Nate and Sam, followed the thresher with a fanning mill and cleaned the wheat.1Lydia Walker Forsgren, History of Box Elder County, (Brigham City: Daughters of Utah Pioneers, 1937), 62.By the time of the 1860 Census, the slave schedule for the Utah Territory lists only 10 slaves in Utah, all in Davis County.2The records regarding the Bankhead family’s slaves is a bit murky. Some reports have him liberating his slaves before leaving Tennessee for Winter Quarters, and the slaves choosing to accompany the family. On the other hand, there are family histories that talk about him sending his slaves to help others (while in Utah), and him loaning them out with the thresher. While they may have been legally free – as seems to be the case based on Census data – they may not have been free in practice.

Samuel Smith and Mads C. Jensen bought the first threshing machine owned in Brigham City, to be freighted in from Council Bluffs, Iowa. However, it had a sad side story. Young Anders Christian Jensen and Henry Tibbets were dispatched to Council Bluffs with four yoke of oxen to haul the huge machine to Utah. Enroute, Jensen was killed by Indians, but Tibbets arrived safely with the much-anticipated thresher.Ibid., 62.

With grain crops being harvested, there was a need for a grist mill to make flour. Forsgren, in the DUP history, dates the original mill to 1855 or 1856, noting that it was not used until 1857 due to crop failures of the two preceding seasons.Ibid., 128-129. Accounts of the proposed city wall place its northeast corner at the mill, or perhaps an under-construction mill. Frederick Huchel, however, dates the stone flouring mill as being completed in time for the harvest of 1857. This first industrial building in the city was built under the supervision of Frederick Kesler, who was appointed by Brigham Young as the church millwright and sent east to learn the latest in mill technology. Upon Kesler’s return in 1854, he was sent to erect a flouring mill for Lorenzo Snow in Brigham City. The mill was co-owned by Young and Snow, even through the Cooperative period.Frederick M. Huchel, “The Box Elder Flouring Mill,” (Salt Lake City: Utah Historical Quarterly, Vol. 56, Winter 1988), 76.Lydia Walker Forsgren, History of Box Elder County, (Brigham City: Daughters of Utah Pioneers, 1937), 259-260.

Construction Industries

The little “pit saw” used to build homes in the Old Fort was soon replaced by commercial sawmills built along Box Elder Creek to make use of water power. The Ettleman brothers built the first sawmill in the mouth of the canyon east of First South. In the city’s first recorded industrial accident, Philip Ettleman was dragged to death by a runaway team while hauling a load of timber on November 16, 1854, and is the first person buried in the Brigham City Cemetery.Ibid., 7.https://www.namesinstone.com/Sources.aspx?dec=342928

Others were soon in the lumber business. In 1856 Alvin Nichols had a sawmill and shingle mill built, with a circular saw run by water power near the mouth of the canyon. Lorenzo Snow and Samuel Smith then built a sawmill run by water power in the same area. In 1863 H. P. Jensen contracted with Martin L. Ensign and Jarvis Johnson to build a mill, where Lyman Wight was hired as manager. That same year Johnson and Ensign built a sawing mill. In 1866 Ephraim Lindsay was foreman of a shingle mill in the mouth of canyon, where charcoal was also burned. Growth in the industry continued with various owners and sawyers during the next decade. Most of the timber was native pine, harvested from the nearby canyons and hillsides east of Brigham City, but by 1866 most of the suitable timber had been removed and the saw mills were moved to Paradise Canyon further south in Perry.Lydia Walker Forsgren, History of Box Elder County, (Brigham City: Daughters of Utah Pioneers, 1937), 126. The need for lumber helped spur road building since raw timber had to be hauled from the nearby canyons. Men were assigned to a certain amount of roadwork, mostly clearing brush and rocks and filling in marshes and swamps. After the Move South in 1858, road building became more of a priority. Forsgren reports that many young men trying to avoid conscription into either the Union or Confederate armies came west, and some of them were hired for road work.Ibid., 141.

Blacksmiths were vital, both for local needs and to serve emigrant trains, freighters and pack animals which soon began coming through the community. William Davis and John D. Rees both followed this trade, and were joined by Rees Richards, John Williams, Edward Lindsay, Hans Peter Jensen, Lars Mortensen, Joseph Packer, Johanson and Sons, A. M. Josephson, Heber Smith, Samuel Jeppson, and William Gidney.Ibid., 94. John D. Rees and John Morgan made nails from scrap iron abandoned along the trail. In 1854 Martin L. Ensign and Simeon Dunn traveled east 300 miles by oxen to obtain scrap iron left behind by emigrants, and made square-headed, four-sided nails still found in remaining early structures.Ibid., 90.

Lime was another material needed for building, and the earliest recorded supplier was Elias Jensen who burned lime in a field west of Brigham City in kilns heated with marsh gas. A better source was later found in the nearby mountains, and James Sheffield operated a kiln near Mantua, where he burned lime used in construction of many local buildings.Ibid., 94.

Home Industries to Business

A number of home industries flourished in the 1850s and 1860s. Some growing into business establishments, others supplying local shops, and others remaining home-based. The following information is from History of Box Elder County compiled by the Daughters of Utah PioneersLydia Walker Forsgren, History of Box Elder County, (Brigham City: Daughters of Utah Pioneers, 1937), 78-95., as well as a business directory in Fife & Petersen.Fife, Veara S., and Chloe N. Petersen, Brigham City, Utah, Residents 1850, 1877, (Brigham City: Golden Spike Chapter, Utah Geological Association, 1976), 148-155.

- Ropemaker John Johnson came to Brigham City in 1854. He grew hemp in the Big Field and pulled it before it was ripe when it was more pliable. Much of this rope was used for bedsteads built with wooden pegs on the sides and ends. Rope was firmly crossed back and forth to create a web that served as the base for a mattress.

- Simeon Dunn planted broom corn and flax in the Big Field, and then in the winter he made brooms. Dampened corn straw was fastened with a rope suspended from the ceiling, spread and fastened in a clamp, then sewn back and forth with linen thread made from the flax, then fitted with handles made from choke cherry limbs.

- Danish potter Ferdinand F. Hansen arrived in Utah in 1852 at age 19 and came to Brigham City in 1854. He established a pottery with a brick kiln and throwing wheel, and located a source of clay near the west end of town. Pots were coated with lead while still damp, then glazed inside and outside prior to firing. He sold his brown ware pottery door to door throughout the county, mostly on a barter basis.

- The city’s first cooper, or barrel maker, H. N. Peterson, emigrated from Denmark in 1856. In addition to barrels made of pine staves with black willow hoops, he made and sold wooden tubs, milk pans, butter churns, bowls and baskets, as well as furniture and brooms.

- Chester Southworth arrived in 1857 and built an adobe home on North Main, with an adobe tannery and shoe shop behind it. His iron vats were sunk deep enough that only the top showed above the surface of the ground, and liquid from native barks was used for tanning. His wife Mary Southworth and daughter Sarah Burbank sewed the shoes by hand with linen thread.

- Ola N. Stohl, a professional tailor from Sweden, opened the city’s first tailor shop in 1866, just one month after his arrival in the community. Lorenzo Snow was among his first customers. Stohl bought his first sewing machine in April 1868, bartering a wagon which had cost him $140. His business was so successful that he soon added employees to help make garments for the community.

- Most spinning and weaving took place in homes. Families owned sheep and carded wool, then spun it into thread and wove cloth and rugs. Flax planted in the Big Field was spun in the same way for linen thread. Native materials were used to create dyes, and sometimes the woolen threads were doubled and twisted into yards for knitting. This was labor intensive, so the arrival of cotton and calico fabric by freighters was a welcome occasion. Women’s clothing was primarily sewn by hand at home. However, pioneer women’s diaries and letters often tell of taking in sewing and making gowns for others, or of trading goods for seamstress or tailoring work. Sarah Hadley Box was the city’s first commercial dressmaker, starting in 1876 and building a business large enough that she hired girls to work in her shop.

- Millinery was another profitable industry suited to home business. In many homes, women wove coarse straw hats for everyday wear, but more elaborate bonnets called for a professional. Mrs. Caroline Smith, wife of Samuel Smith, was probably the first local milliner. She began in 1857 in the living room of their home on the corner of Forest and Main and continued the trade for some 15 years, assisted by her sister Maria, who was also a sister wife.

- Arriving in 1863, Mary Ann Jackson Graham made Scotch hats and caps from cloth brought across the plains from England. Anna Hansen sent her little girls down to Main Street to sell her braided straw hats to passersby. Mrs. Mary Stark conducted a millinery school for girls from 1873 to 1875, where she taught how to braid and sew straw hats as well as make artificial flowers.

- Although family meals were prepared at home, there were vital ingredients needed for cooking. The most basic of these was salt. Taking advantage of the nearby natural resources, George W. Parsons was the first to take up salt making as a business, setting up a furnace to boil salt water in 1864 at the mouth of the Bear River and Great Salt Lake. He took in William Neeley as a partner and they built another boiler and furnace. The demand for salt kept them busy:

“We kept them running day and night. We each had a yoke of oxen at our camp and we used them to haul the salt water from the lake to our evaporators and also to drag the willows from the banks of the river to our furnace.”Lydia Walker Forsgren, History of Box Elder County, (Brigham City: Daughters of Utah Pioneers, 1937), 88.

- Sugar was scarce so the pioneers planted sugar cane in the Big Field and manufactured molasses by crushing the cane and extracting the juice. Lars Christensen and George Parsons are credited with operating the first local molasses mill at First North and Fourth West in the early 1860s.

- Brigham City’s first commercial baker and candymaker was George L. Graehl, Sr. who arrived from Bavaria in 1855, where he had learned the confectioner trade. He made and sold candy, fancy cakes and bread at his home on South Main Street, mostly in trade with local people but for precious cash from freighters. He and his wife Charlotte also supplied the bread for Sacrament meetings.

- For Annorah Coleman Boden, candymaking became the means of raising her family. She was left widowed and penniless with seven children just two days after her arrival in Salt Lake City in 1868, and soon joined a married daughter in Brigham City. She began making candy in a small kettle over the fireplace, building up a trade that soon grew to supplying local merchants. The arrival of railroad workers in 1868-69 provided a larger market and spread the fame of her fine candies. She was eventually able to invest in modern equipment for her candy and to build a fine home on West Forest, which she and a daughter later operated as a boarding house. Her candy recipe has been handed down through the family and is still made by her descendants.Sarah Yates, “First Industries began with family,” Box Elder Journal, (Brigham City: March 10, 1997), 9.

- Another “kitchen craft” was that practiced by Olivia “Auntie” Box who made and sold starts of yeasts to other homemakers.

- It didn’t take long for settlers to begin selling merchandise, including spices and cooking utensils, buttons and scissors, and other articles not easily produced at home. Jonathan C. Packer opened a small notion store in the front room of his home sometime prior to 1862, with his wife as clerk. Harriet Snow, Samuel Smith and his wives, Morris D. Rosenbaum, and William C. Thomas owned downtown businesses. They offered wares brought in by freighters, as well as provided by local craftspeople, farmers, and in their own home industries.

- The Boothe, Wilson, and Coray store opened in 1869 near the Boothe Hotel south of the courthouse, and evolved into a long-lasting Boothe and Peirce Store. Chris Holst began selling goods door-to-door from a basket and later erected a small store on South Main. Photographer Jens C. Gasberg began making tintype pictures in 1873 in his home, then moved his gallery downtown as he went to more modern photography. Morris Rosenbaum, one of the first Jewish converts, who in 1867 became Lorenzo Snow’s son-in-law, gradually built up a business housed in a two-story building on South Main Street.

Next: Business After The Co-op

Add comment